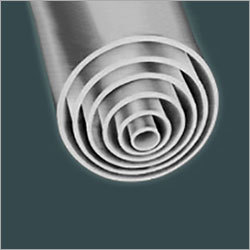

Stainless Steel Seamless Pipes

Product Details:

- Surface Finish Annealed, Polished, Pickled, Mill Finish, Bright

- Alloy Yes, alloyed as per grade specifications

- End Protector Plastic Caps on Pipe Ends

- Application Oil & Gas, Petrochemical, Power Plants, Pharmaceutical, Food Processing, Construction, Automotive

- Connection Plain End, Bevel End, Threaded

- Other Material Upon request (Nickel alloys, Duplex, Super Duplex)

- Product Type Stainless Steel Seamless Pipe

- Click to View more

X

Stainless Steel Seamless Pipes Price And Quantity

- 1 Unit

Stainless Steel Seamless Pipes Product Specifications

- 1 mm to 20 mm (customizable)

- Stainless Steel Seamless Pipe

- 6 mm to 610 mm

- OD 1%, Thickness 10%, Length 10 mm

- Stainless Steel

- Up to 12 meters (standard or custom lengths available)

- Yes, alloyed as per grade specifications

- Plastic Caps on Pipe Ends

- AISI, ASTM, EN grades available

- Pickled and Passivated, as required

- Round, Square, Rectangular

- Annealed, Polished, Pickled, Mill Finish, Bright

- Upon request (Nickel alloys, Duplex, Super Duplex)

- Silvery, Metallic

- Cold Drawn, Hot Rolled

- 304, 304L, 316, 316L, 321, 347, 310S, 317L, 904L and other ASTM/ASME/EN grades

- ASTM A312, ASTM A213, ASTM A269, EN 10216-5, DIN, JIS

- Oil & Gas, Petrochemical, Power Plants, Pharmaceutical, Food Processing, Construction, Automotive

- Seamless Pipe

- Plain End, Bevel End, Threaded

Stainless Steel Seamless Pipes Trade Information

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA)

- 1500 Unit Unit Per Month

- Africa, Middle East

Product Description

We are stockiest and dealers of Stainless Steel Seamless Pipes that are available in technical specifications ad detailed to us by our clients. Known for availability in varied sizes, our range of Stainless Steel Seamless Pipes meet variegated industry specific requirement and in sure to be made available to buyers as per their requirement within a stipulated time frame. Sourced from industry established vendors, we promise durability and functionality in our range and are committed to deliver only the best of the products to our clients.

Features

- Durable

- Available in different sizes

- Wide functionality

- Cost-effective

Superior Performance in Challenging Conditions

Designed for resilience, our stainless steel seamless pipes can withstand temperatures up to 1150C and harsh corrosive media. Their excellent mechanical properties, supported by a maximum pipe hardness of 80 HRB and high pressure ratings as per ASME B31.3, guarantee dependable performance across automotive, construction, and other energy-intensive sectors. With excellent weldability, they integrate seamlessly into diverse piping systems.

Comprehensive Customization and Quality Assurance

Choose from a variety of available grades, shapes, and finishes, including round, square, and rectangular configurations. Outer diameters range from 6 mm to 610 mm, with thicknesses up to 20 mm and custom sizes upon request. Each pipe is supplied solution annealed and passivated, certified under EN 10204/3.1 or 3.2, and carefully packaged for secure delivery. We offer lead times of 2-6 weeks, ensuring timely and reliable service.

FAQs of Stainless Steel Seamless Pipes:

Q: How are stainless steel seamless pipes packaged and delivered to ensure their safety?

A: Our pipes are bundled with steel strips, fitted with plastic caps, and packaged according to client requirements to prevent damage during transit. This ensures pipes arrive in pristine condition, ready for installation.Q: What quality certifications do your seamless pipes carry?

A: We provide test certificates in accordance with EN 10204/3.1 and 3.2, confirming compliance with international standards like ASTM A312, ASTM A213, ASTM A269, and EN 10216-5. Each batch is fully traceable and tested for critical parameters.Q: When can custom sizes and lengths for seamless pipes be requested?

A: Custom sizes, thicknesses, and lengths can be requested at the time of order. Our standard production accommodates outer diameters from 6 mm to 610 mm, thicknesses of 1 mm to 20 mm, and lengths up to 12 meters. Customization is available based on project requirements.Q: What is the process for ensuring corrosion resistance in your pipes?

A: Our pipes undergo pickling and passivation treatments, which remove surface impurities and enhance corrosion resistance. This, combined with the use of high-quality stainless steel grades, ensures superior performance in corrosive industrial environments.Q: Where can these stainless steel seamless pipes be used?

A: These pipes are extensively used in oil & gas, petrochemical, power plants, pharmaceutical, food processing, construction, and automotive industries due to their excellent mechanical properties, temperature and corrosion resistance.Q: How does the solution annealing and passivation process benefit the pipes?

A: Solution annealing relieves internal stresses and enhances the ductility and mechanical properties of the pipe, while passivation forms a protective layer, significantly boosting resistance to oxidation and corrosion for longer service life.Q: What are the main advantages of choosing seamless pipes over welded pipes?

A: Seamless pipes offer superior strength, uniformity, and resistance to high pressure and temperature conditions. They are less susceptible to leakage or failure, making them ideal for critical applications in demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Stainless Steel Pipes' category

|

HANUMAN POWER TRANSMISSION EQPT. P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |